Dock Leveler พื้นปรับระดับ

Electrohydraulic dock levelers with hinged lip of DLHHI series are an optimal solution, which provide the pick-and-place operation and ensure fast loading and unloading. When activated, the leveler is lifted and the lip opens while turning. Next, the platform is lowered until it reaches the floor of the vehicle body. The system is ready for operation. After the work is completed the leveler is lifted, the lip lowers and takes a vertical position, then the platform is returned its original position. Installation can be carried out by both, embedded and suspended installing methods.

Main advantages:

- self-cleaning hinges between the leveler and lip;

- ramp length is 400 mm (can be optionally increased to 500 mm);

- when working with a truck having skewed platform, the leveler can tilt sideways to 100 mm;

- due to the yellow-black signal strip, one can see that the platform is located above the level of the ramp;

- the surface is made of lentil sheet to provide a better adhesion of the forklift wheel;

- the lip supports ensure a safe transverse movement on the leveler in the closed position;

- the safety system instantly stops the hydraulic leveler in the case of hose breakage or in case of unauthorized departure of the car during loading/unloading works;

- side airbags prevent the staff feet getting into the gap between the leveler and the pit during operation;

- locking mechanism (repair backup) provides a safe leveler maintenance and repair

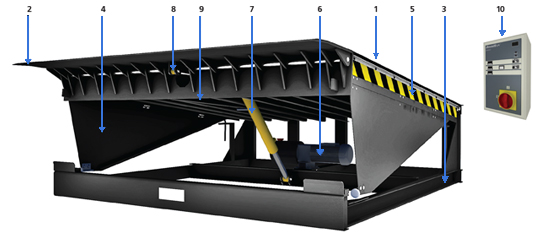

1. Platform cover

2. Lip

3. Frame

4. Side curtain airbags

5. Signal black and yellow stripes

6. Hydraulic Pump

7. Lifting cylinder

8. Cylinder lip

9. Backup repair

10. Control unit

Dock levelers are covered with embossed steel sheet with a thickness of 6-8 mm, where the embossing height is 0,6-2,4 mm. Dock levelers can be manufactured with embossed steel sheet with a thickness of 6 mm where the embossing height is 0.6-1.8 mm, if these are intended for loading and unloading operations using a standard forklift. Dock levelers can be also produced with embossed steel sheet of 8 mm thickness where the embossing height is 0.8-2.4 mm, if these are intended to be used with high point load equipment (eg. electric stackers).

There might be a potential distortion of the platform top sheet, which does not affect leveler operation. The lip is made of embossed steel sheet with 12 mm thickness, where the embossing height is 1,2-3,6 mm. The longitudinal beams may be made of 100/120 mm or L-shaped profile with dimensions 140x40x4 mm, the frame — 100/120 mm. In case when the length of the platform is greater than 3500 mm, the longitudinal beams and frame are made of I-beam 120 mm.