Electrohydraulic dock levelers with telescopic lip of DSI series are the most effective solution for accessing the load from the warehouse to the truck during loading and unloading operations. These levelers are used when a precise lip positioning is needed to the vehicle body, such as the lateral load, as well as the minimum distance between the edge of the vehicle body and the load located inside it. The segments of the lip, allow operation with vehicles whose width is narrower than the width of the leveler. Operation principle is that when activated, the leveler is lifted and the lip is pushed, then the platform is lowered until the lip reaches the floor of the vehicle. After the completion of loading and unloading the leveler is raised again, the lip retracts, the platform returns to its original position. Adjustment is performed by suspended or embedded installation type.

Main advantages:

- the length of the lip is 500/1000 mm;

- when working with truck that has a skew, the side tilt is possibile to 100 mm;

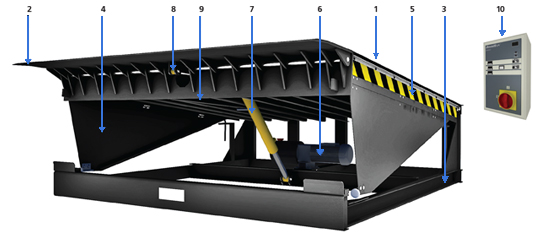

- due to yellow-black signal strip, one can see that the platform is above the level of the ramp;

- the surface of the platform is made of lentil sheet to provide a better adhesion of the forklift wheel;

- provides safe transverse movement on the leveler;

- safety system instantly stops the hydraulic leveler in the case of hose breakage or unauthorized departure of the vehicle during operations;

- locking mechanism ensures a safe leveler maintenance and repair.

1. Platform cover

2. Lip

3. Frame

4. Signal black and yellow stripes

5. Hydraulic pump

6. Lifting cylinder

7. Cylinder ramp

8. Backup repair

9. Front PVC-curtain

10. Control unit

Dock leveler surface is made of embossed steel sheet with a thickness of 8-10 mm, where the embossing height is 0.8-3 mm. Dock levelers with telescopic lip may be produced with embossed steel sheet of 8 mm thickness with embossing height is 0.8-2.4 mm, in cases when standard forklifts will be used during loading and unloading operations. Dock levelers made with embossed steel sheet of 10 mm thickness and embossing height of 1-3 mm can be produced in cases when the load on the platform is up to 10,000 kg. There might be a potential distortion of the platform, which does not affect product operation.

The lip is made of embossed steel sheet of 12 mm thickness where the embossing height is 1,2-3,6 mm. The longitudinal beams may be made of 100-120 mm or L-shaped profile with dimensions 187x70x4 mm, the frame of U-profile 100-120 mm.